About Us

Who We Are?

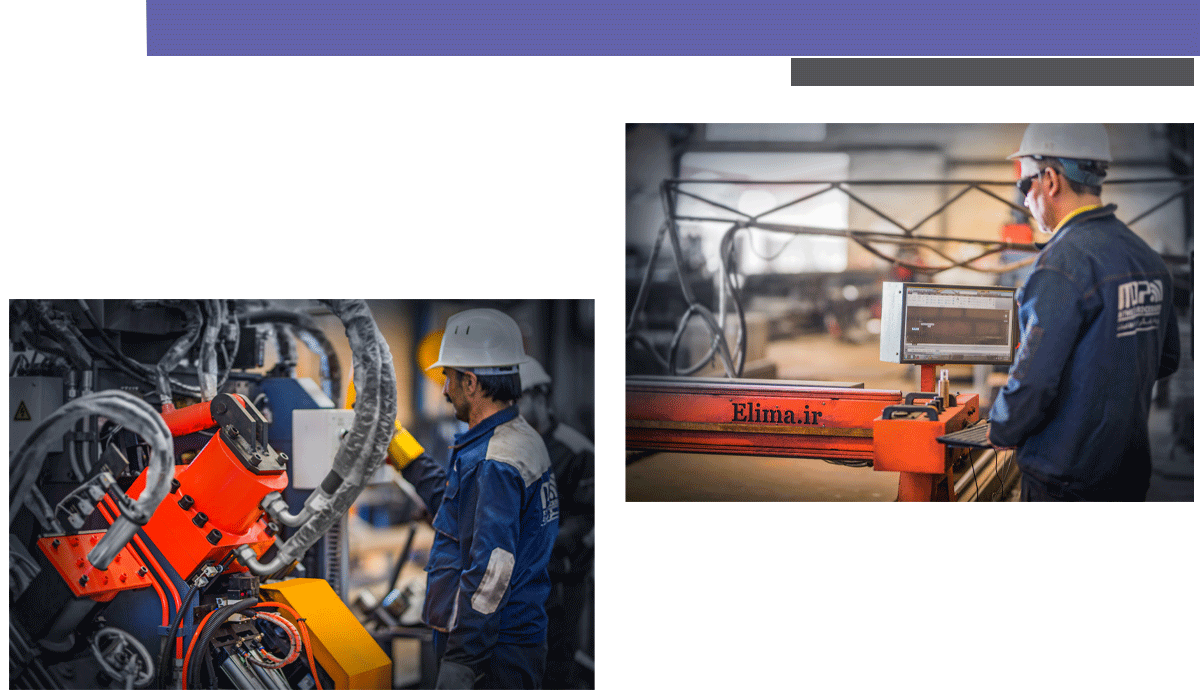

Towerist, established in Turkey with over 20 years of experience, is a leading manufacturer specializing in the design, production, and galvanization of high-quality steel structures. Our expertise lies in providing power transmission towers, telecommunication towers, and high-voltage substation steel structures. Towerist combines skilled professionals with fully automated

machinery to ensure compliance with international standards and deliver exceptional products.Over the years, we have built long-lasting relationships with our clients, and we take pride in providing reliable, durable solutions that exceed customer expectations. With a production capacity of more than 25,000 MT of lattice steel structures, Towerist is well-equipped to handle complex projects globally.

CEO Message

Vision, Mission & Values

Vision

Mission

Values

- Respect for Nature: We prioritize sustainable practices and environmental protection.

- Commitment and Excellence: We are dedicated to providing the best solutions for our clients.

- Teamwork and Partnership: Collaborative efforts are key to our success.

- Integrity: We maintain transparency and ethical practices in all our operations.

- Innovation: Continuously improving and evolving through new technologies and methods.

Our Team

Our team consists of highly skilled professionals who work tirelessly to deliver innovative solutions. From engineers to project managers, each member contributes to our ongoing success.

Quality Assurance & Control

The quality assurance & control department is one of the important units in the excellence of Towerist products. The responsibility of this process is to achieve all the desired features in a product in accordance with international and national standards and according to the request of the employer.

The main duties of this unit are:

- Chemical, visual and dimensional control of raw materials before and during their entry into the warehouse and compliance with the purchase documents

- Visual and dimensional control of the parts made in the manufacturing workshop and compliance with the part drawings

- Welding control and performing PT, VT, UT tests if necessary and welding round control

- Control and supervision of the installation of the produced sample and compliance with the installation plans and issuance of transport permit to the galvanizing workshop

- Controlling the number and weight of the produced parts before transporting them to the galvanizing workshop and complying with the project material list

- Control during galvanizing operation

- Controlling during packing and complying with the packing list and issuing permission to transport to the customer’s site

The Quality assurance and control unit is obliged to report the smallest discrepancy to the management directly through pre-arranged forms and issue an order to stop production, if necessary.

Towerist compiles and prepares the quality control and assurance program (QCP) before the start of each project.

Research & Development

Health, safety and environment (HSE)

Some of the most important goals of this department are to create and improve the level of health and safety culture in the industry. Toweirst has been able to establish an integrated management system in the field of health, safety and environment in its group by receiving the HSE-MS certificate. The most important HSE requirements in Towerist factory are:

- The presence of the HSE manager in the workshop

- Logo, signs of work clothes and its material

- Welding and cutting requirements

- Safety requirements for work at height

- Fall prevention equipment

Membership and Certificates

Towerist is proud to be a member of several prestigious industry associations and holds certifications that demonstrate our commitment to excellence and compliance with international standards.