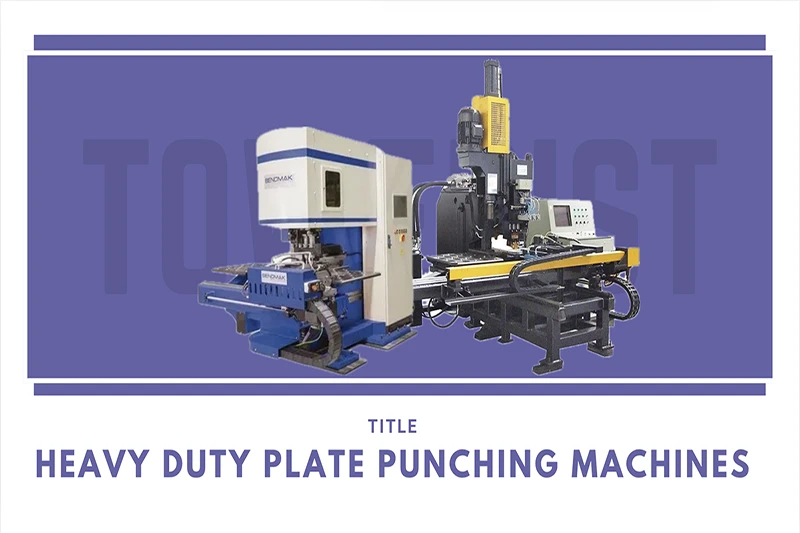

Heavy Plate Punching Machine: The Essential Tool for Industrial Applications

Introduction: In the world of industrial manufacturing, precision and efficiency are paramount. Heavy plate punching machines, or punch presses, are essential tools used to create precise holes or shapes in heavy metal plates. These machines are crucial in industries such as construction, automotive, energy, and metal fabrication. This blog will explore the importance, types, features, and advantages of heavy plate punching machines, shedding light on how they contribute to the efficiency of various industrial operations.

What is a Heavy Plate Punching Machine?

A heavy plate punching machine is a mechanical device used to create holes, slots, or other shapes in thick metal plates by applying high pressure. These machines are designed to work with materials such as steel, aluminum, and other alloys, with thicknesses ranging from several millimeters to several centimeters. The punching process involves feeding the metal plate into the machine, where it is positioned under a punch tool that applies force to cut the material, creating the desired pattern.

Click to read the article onIntroduction to Drilling and Punching Machines for Steel Tower Structures

Types of Heavy Plate Punching Machines:

There are several different types of heavy plate punching machines, each designed for specific applications and materials. Below are the most common types:

- Mechanical Punching Machines:

- These machines use a flywheel or an electric motor to generate the punching force. They are known for their fast punching speeds and are ideal for high-volume operations. Mechanical punching machines are often used in industries where rapid production and efficiency are critical.

- Hydraulic Punching Machines:

- Hydraulic punching machines use hydraulic pressure to exert force on the punch tool. These machines offer greater control over punching force and are often used for more complex or thick materials. They are ideal for applications that require high precision and heavy-duty punching.

- CNC Punching Machines:

- CNC (Computer Numerical Control) punching machines combine advanced technology with heavy plate punching capabilities. These machines are fully automated and controlled by a computer, allowing for highly precise and intricate patterns to be punched in various materials. They are commonly used in industries that require high-quality results and minimal manual intervention.

Click here for more information about the types of power transmission towers

Applications of Heavy Plate Punching Machines:

Heavy plate punching machines have a wide range of applications across different industries, including:

- Construction Industry: Punching machines are used to create holes and slots in steel plates for structural components, such as beams, columns, and trusses. This ensures that the materials fit together perfectly during assembly.

- Automotive Industry: In automotive manufacturing, punching machines are used to create precise holes for parts like brackets, chassis components, and exhaust systems.

- Energy Sector: In the energy industry, particularly in power plants and oil rigs, heavy plate punching machines are used to produce parts for turbines, generators, and pipelines. The durability and precision of these machines are crucial in these high-stress environments.

- Metal Fabrication: Heavy plate punching machines are frequently used in metal fabrication shops to create custom parts, brackets, and enclosures for various applications.

Key Features and Benefits of Heavy Plate Punching Machines:

- Precision and Accuracy:

- Heavy plate punching machines offer high precision, ensuring that the holes or shapes created are consistent and meet exact specifications. This is especially important in industries that require tight tolerances, such as aerospace and automotive.

- Increased Efficiency:

- These machines are designed to operate quickly, allowing manufacturers to increase their productivity. High-speed punching capabilities reduce downtime and lead times, enabling companies to meet tight deadlines.

- Cost-Effectiveness:

- While heavy plate punching machines may require a significant initial investment, they can save money in the long term by reducing labor costs and minimizing material waste. Their efficiency also leads to increased throughput and lower production costs.

- Versatility:

- With the ability to work with various materials and thicknesses, heavy plate punching machines can be used for a wide range of applications. Some machines are also capable of performing additional operations, such as shearing, bending, and embossing, making them versatile tools in a manufacturing facility.

- Automation and Control:

- Many modern punching machines are CNC-controlled, which allows for precise automation of punching operations. This reduces the need for manual labor and minimizes the risk of human error, resulting in higher-quality products and reduced production costs.

Choosing the Right Heavy Plate Punching Machine:

When selecting a heavy plate punching machine, there are several factors to consider:

- Material Type and Thickness: Different machines are suited for different types of materials and thicknesses. It’s essential to choose a machine that can handle the specific materials used in your production process.

- Production Volume: If you have high production demands, you may need a machine with higher punching speeds and greater durability. Consider whether you need a mechanical, hydraulic, or CNC punching machine based on the volume and complexity of your tasks.

- Precision Requirements: Some industries require extremely high precision in punching operations. CNC punching machines are ideal for these applications, as they offer the highest level of accuracy.

- Maintenance and Support: Like any industrial equipment, heavy plate punching machines require regular maintenance to ensure optimal performance. Consider the availability of spare parts and the support services offered by the manufacturer.

When constructing transmission towers, having access to advanced machinery is crucial for achieving precision and efficiency. Towerist provides valuable insights into the machinery used in the production of these towers, including CNC machines and other specialized equipment. These tools play an essential role in ensuring the strength and durability of each tower. To learn more about the machines and equipment involved in tower construction, visit our services page for detailed information and expert recommendations.

Conclusion:

Heavy plate punching machines are indispensable tools in modern industrial manufacturing. Their ability to create precise, high-quality holes and shapes in a variety of materials makes them essential in industries ranging from construction and automotive to energy and metal fabrication. By choosing the right type of punching machine for your specific needs, you can improve production efficiency, reduce costs, and ensure that your manufacturing operations run smoothly.

As technology advances, these machines continue to evolve, offering even greater precision, efficiency, and automation. Whether you’re looking to optimize your manufacturing processes or invest in new equipment, a heavy plate punching machine is a valuable asset that can drive productivity and growth in your business.

Resources